Thursday, September 20, 2018

Thursday, August 23, 2018

Tuesday, August 21, 2018

Monday, July 9, 2018

Tuesday, November 14, 2017

John Deere Service Advisor AG 02.2016

7:56 PM

assembly and disassembly engine

,

electrical wiring diagram

,

Heavy Equipment Manuals

,

hydraulic diagram

,

john deere

,

repair manual

,

transmission

John Deere Service Advisor AG 02.2016

screen shoots

John Deere Service Advisor AG 02.2016

John Deere Service Advisor Agriculture 2016 workshop manual, repair manual, electrical wiring diagram, hydraulic diagram, assembly and disassembly engine, transmission.

John Deere Service Advisor 4.2 service and workshop manual, repair manual, dealer technical assistance, diagnostics, connection readings, calibrations, interactive tests, specification, tools.

John Deere 4WD Loader

John Deere AG Management Solutions

John Deere Attachment

John Deere Axles

John Deere Backhoe

John Deere Boom

John Deere Combines and Headers

John Deere Commercial

John Deere Commercial Worksite Products

John Deere Cotton Harvesting

John Deere Excavator

John Deere Forklift

John Deere Harvester

John Deere Hay and Forage

John Deere Information

John Deere JD Miscellaneous Equipment

John Deere LG Attachments

John Deere Mate. Hand Cut. and Shredders

John Deere OEM Engines

John Deere PTO

John Deere Planetary Drive

John Deere Planting and Seeding

John Deere Readings

John Deere Riding Lawn Equipment

John Deere Skid Steer

John Deere Sprayers

John Deere Sugar Cane

John Deere Sugar Cane Harvesters

John Deere Tillage

John Deere Tractor Attachments

John Deere Tractors

John Deere Transmission

John Deere Utility

John Deere Utility Vehicles

John Deere Worksite Pro Attachment

John Deere Service Advisor 4.2 service and workshop manual, repair manual, dealer technical assistance, diagnostics, connection readings, calibrations, interactive tests, specification, tools.

John Deere 4WD Loader

John Deere AG Management Solutions

John Deere Attachment

John Deere Axles

John Deere Backhoe

John Deere Boom

John Deere Combines and Headers

John Deere Commercial

John Deere Commercial Worksite Products

John Deere Cotton Harvesting

John Deere Excavator

John Deere Forklift

John Deere Harvester

John Deere Hay and Forage

John Deere Information

John Deere JD Miscellaneous Equipment

John Deere LG Attachments

John Deere Mate. Hand Cut. and Shredders

John Deere OEM Engines

John Deere PTO

John Deere Planetary Drive

John Deere Planting and Seeding

John Deere Readings

John Deere Riding Lawn Equipment

John Deere Skid Steer

John Deere Sprayers

John Deere Sugar Cane

John Deere Sugar Cane Harvesters

John Deere Tillage

John Deere Tractor Attachments

John Deere Tractors

John Deere Transmission

John Deere Utility

John Deere Utility Vehicles

John Deere Worksite Pro Attachment

DVD : 7+1 setup

contact us

info@autotech4you.com

phone number , whats app , imo : 00201011862525

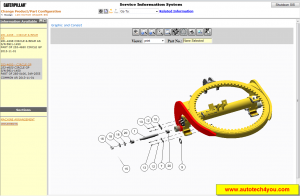

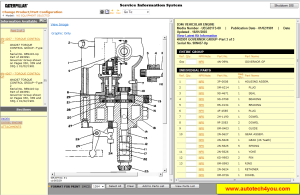

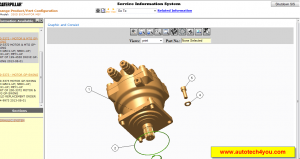

Caterpillar sis 3D 2017

6:19 PM

caterpillar

,

Heavy Equipment Manuals

,

heavy equipment spare catalouges

,

wiring diagrams

,

workshop manuals

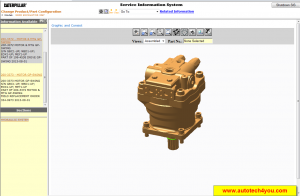

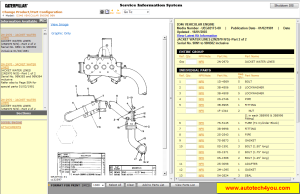

Caterpillar sis 3D 2017

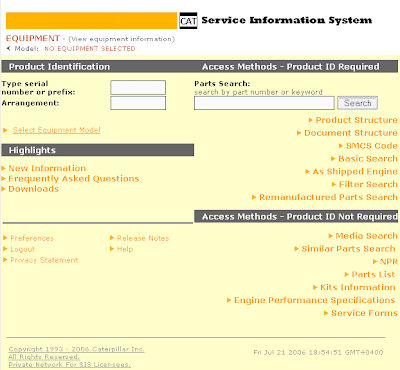

SIS is the electronic service tool that Caterpillar dealers, customers and employees rely on for their parts and service information needs. SIS provides information for all Caterpillar machines and engines from 1977. SIS is available on the Internet, DVDs and a network version based on the DVD standalone application.

SIS Web is updated continually and is the most complete and up to date version of SIS. SIS DVD and Network SIS use the same information that is located on the monthly data DVD'S. The time required to stage and ship the DVD'S to Dealer's and Customer's accounts for the delay in information that may be available from SIS DVD/Network.

SIS DVD is the standalone version of SIS and is required when the Caterpillar Inc. server for either SIS Web or the Dealer server for Network SIS is not available. Field Mechanics may be the largest group that uses SIS DVD. All three versions of SIS require an Internet Browser to display SIS information.

Caterpillar STW

The Service Technician Workbench is an integrated package of software tools, designed to assist the Caterpillar Service Technician during the machine repair process.

STW provides common installation of the following service software applications: STW Toolbar (STW Lauchpad), Service Information System (SIS), Cat Electronic Technician (Cat ET), CBT Component Based Troubleshooting (CBT), Technical Analisis I (TA1) & Technical Analisis II (TA2), and Service Report.

STW Features:

Allows user to send data from SIS, TA and Cat ET to an Electronic Service Report. All information about the repair is in one location.

Allows user to attach Cat ET Warranty Reports to the STW service report.

Allows user to attach digital photos to further document the repair.

A single source of support ? DDS Support Center

Electronic service reports are easier to archive than paper service reports.

Integration between Component Based Troubleshooting (CBT), Service Information System (SIS), Cat Electronic Technician (Cat ET), Flash File Search and Service Report.

The DBS Upload utility increases dealer efficiency by eliminating the need for the technician to re-type data into the service report, already created in DBS. This information is sent from DBS to STW to create a STW service report.

STW Lauchpad

The STW Launchpad allows to you: Conveniently launch Service Software Applications, Manage some common SIS/CBT preferences.

STW Service Report

The STW Service Report is a tool to help you collect, report, and organize your service jobs.

- Allows for complete documentation of your repair.

- Reduce duplicate typing of Service Reports

- Easy to read

- Spell check

Easy integration with Dealer Business System (both DBS and DBSi):

Download header information from DBS

Upload service information to DBS after your job is completed

Collect information from other service tools, including:

Parts lists from SIS

ECM summaries and reports from Cat ET

Inspection lists from Technical Analysis (TA)

Component Based Troubleshooting

Component Based Troubleshooting (CBT) helps the technician troubleshoot symptoms and codes for Caterpillar engines and machines. After identifying a symptom, the technician is presented with a list of components that, if not operating properly, may cause the symptom. By using the information provided for each component, the technician can identify the root cause of the symptom and fix the problem. The technician is also presented with a list of available ECMs and codes for the selected model to troubleshoot diagnostic codes. In addition, CBT gives the technician links to related information for symptoms and codes in the Service Information System (SIS).

SIS Web is updated continually and is the most complete and up to date version of SIS. SIS DVD and Network SIS use the same information that is located on the monthly data DVD'S. The time required to stage and ship the DVD'S to Dealer's and Customer's accounts for the delay in information that may be available from SIS DVD/Network.

SIS DVD is the standalone version of SIS and is required when the Caterpillar Inc. server for either SIS Web or the Dealer server for Network SIS is not available. Field Mechanics may be the largest group that uses SIS DVD. All three versions of SIS require an Internet Browser to display SIS information.

Caterpillar STW

The Service Technician Workbench is an integrated package of software tools, designed to assist the Caterpillar Service Technician during the machine repair process.

STW provides common installation of the following service software applications: STW Toolbar (STW Lauchpad), Service Information System (SIS), Cat Electronic Technician (Cat ET), CBT Component Based Troubleshooting (CBT), Technical Analisis I (TA1) & Technical Analisis II (TA2), and Service Report.

STW Features:

Allows user to send data from SIS, TA and Cat ET to an Electronic Service Report. All information about the repair is in one location.

Allows user to attach Cat ET Warranty Reports to the STW service report.

Allows user to attach digital photos to further document the repair.

A single source of support ? DDS Support Center

Electronic service reports are easier to archive than paper service reports.

Integration between Component Based Troubleshooting (CBT), Service Information System (SIS), Cat Electronic Technician (Cat ET), Flash File Search and Service Report.

The DBS Upload utility increases dealer efficiency by eliminating the need for the technician to re-type data into the service report, already created in DBS. This information is sent from DBS to STW to create a STW service report.

STW Lauchpad

The STW Launchpad allows to you: Conveniently launch Service Software Applications, Manage some common SIS/CBT preferences.

STW Service Report

The STW Service Report is a tool to help you collect, report, and organize your service jobs.

- Allows for complete documentation of your repair.

- Reduce duplicate typing of Service Reports

- Easy to read

- Spell check

Easy integration with Dealer Business System (both DBS and DBSi):

Download header information from DBS

Upload service information to DBS after your job is completed

Collect information from other service tools, including:

Parts lists from SIS

ECM summaries and reports from Cat ET

Inspection lists from Technical Analysis (TA)

Component Based Troubleshooting

Component Based Troubleshooting (CBT) helps the technician troubleshoot symptoms and codes for Caterpillar engines and machines. After identifying a symptom, the technician is presented with a list of components that, if not operating properly, may cause the symptom. By using the information provided for each component, the technician can identify the root cause of the symptom and fix the problem. The technician is also presented with a list of available ECMs and codes for the selected model to troubleshoot diagnostic codes. In addition, CBT gives the technician links to related information for symptoms and codes in the Service Information System (SIS).

22 DVD

Caterpillar sis 3D 2017

يمكن التواصل معنا عن طريق البريد الإلكترونى

info@autotech4you.com

أو يمكن الأتصال بنا على 01011862525

ومن خارج مصر على

00201011862525

رقمنا بالمملكة العربية السعودية

0590560442

Hint

Content is displayed Does not represent any company, and we are not agents for any destination

المحتوى المعروض غير خاص باى شركة ونحن لسنا وكلاء لاى جهة

KOMATSU linkone EPC 2017

1:28 PM

Crawler Dozers and Loaders

,

engine

,

Komatsu Hydraulic Excavator Attachments

,

Komatsu Hydraulic Excavators

,

Komatsu Mobile Crushers

,

parts books

,

spare parts

,

transmission

KOMATSU linkone EPC 2017

KOMATSU linkone EPC 2017

Komatsu Linkone electronic spare parts catalog Komatsu, parts books Komatsu Crawler Dozers and Loaders, Komatsu Hydraulic Excavator Attachments, Komatsu Hydraulic Excavators, Komatsu Mobile Crushers, Komatsu Motor Graders, Komatsu Motor Scrapers, Komatsu Stationary Generators, Komatsu Construction Trucks, Komatsu Construction Wheel Dozers, Komatsu Wheel Loaders.

Komatsu Construction spare parts catalogue, parts manuals models list:

Komatsu Articulated Dump Trucks

Komatsu Bulldozers

Komatsu Crawler Excavators

Komatsu Crawler Loaders

Komatsu Engine Generator Sets

Komatsu Engines

Komatsu Mobile Crushers And Recyclers

Komatsu Motor Graders

Komatsu Motor Scrapers

Komatsu Pipe Layers

Komatsu Rigid Dump Trucks

Komatsu Rollers, Komatsu Trash Compactors And Loaders

Komatsu Construction Wheel Dozers

Komatsu Wheel Loaders

Komatsu Wheeled Excavators

KOMATSU linkone EPC 2017

Monday, November 13, 2017

BOSCH ESI tronic 2017

BOSCH ESI tronic 2017

description :

The BOSCH Esi tronic supports a lot of languages, has the good interface, allows to search under number of detail Bosch or any other manufacturer, gives out the information on application concrete spare parts on marks and models. The great bulk of the information is submitted on machines since 1971, but something is and on earlier samples. The program BOSCH Esi tronic is the valuable manual for those who is engaged in repair and delivery of spare parts for lorries, contains the full information on pneumatic, electronic and to fuel systems European, and also in part the American and Japanese lorries. Installation of the program is simple and does not cause questions. Work directly from DVD or installation of disks on the winchester is possible.That is on Bosch Esitronic -* CD - A Spare parts and the equipment* CD - C Diagnostics* CD - D Spare parts for diesel engines* CD - E Spare parts for electricians* CD - F Archival* CD - K the Manual for components* CD - M Mechanics* CD - P Electric circuits* CD - W Control values of fuel pumps of a high pressure and diesel engines BOSCH ESI TRONIC

BOSCH ESI tronic 2017

| Region: | All regions | |

| Languages: | English, Dutch, Spanish, Italian, German, Russian, Turkish, French, Swedish | |

| OS: | WinXP , Win 7 | |

BOSCH ESI tronic 2017

Wednesday, November 8, 2017

Cummins Insite 8 + INCAL 08.2017

Cummins Insite 8 + INCAL 10.2017

screen shoots

Cummins Insite 8 + INCAL 08.2017

Cummins INSITE v8, diagnosis software for Cummins Engines & ECM Units.

Cummins NSITE v8 Announcement

We are pleased to announce that INSITETM v8 is now in production. This latest version of INSITETM supports all new and existing Cummins engine platforms.

Cummins Insite New Features and Support

* INSITE v88 added support for these engines:

o ISLe4.5 - CM2150E

o ISLe5 - CM2150E

o ISMe4 - CM876

Cummins INSITE v8 added functionality (See Link for Details)

o Inactive Fault Code Reset with ECM Multi-Level Security

o Context Sensitive Help/F1 Help

o 30 Second Key Switch Timer

o INSITE Exit Confirmation Box

o Data Link Adapter Auto Configure

Cummins New ECM Diagnostic Tests

o Air Fuel Ratio Test

o Manual Fuel Control Valve Adjustment

o Aftertreatment High NOx Reset Test

Cummins INCAL 2017

Automotive Calibrations Data for Cummins Insite

What is INCAL?

The INCAL is a set of 3 DVD which contain the latest revision of ECM Calibrations. They are released and sent out monthly to INCAL Subscribers. Please contact your Cummins distributor for more information

Cummins Insite 8 + INCAL 08.2017

Cummins QuickServe Engines

3:43 PM

Cummins QuickServe Engines spare parts catalog

,

operators manuals

,

service information

,

technical service bulletins

,

workshop manuals

Cummins QuickServe Engines

برنامج صيانه وقطع غيار محركات كامنز يحتوى على شرح ميكانكيا كامل لجميع اجزاء المحركات ارقام قطع الغيار الاصليه

screen shoots

Cummins QuickServe Engines

Cummins QuickServe Engines

Cummins QuickServe Engines spare parts catalog, service information, workshop manuals, technical service bulletins, operators manuals, labour times for all Cummins Engines.

Cummins Quickserve catalog includes:

Cummins Middle Power Range

Cummins Heavy Duty

Cummins High Horsepower

Cummins ISB, ISBe, QSB CM800, 850

Cummins A1400

Cummins A1700

Cummins A2000

Cummins A2300

Cummins B Gas Plus, B LPG Plus, B5.9LPG, G5.9, B5.8 Gas

Cummins B4.5s

Cummins B6.7s

Cummins C Gas Plus, C8.36, G8.3

Cummins G28

Cummins G3.9

Cummins G50

Cummins GTA855 CM558 N101, G855, G14, GTA855 CM558 N101, G855

Cummins ISB, ISBe CM800

Cummins ISB, QSB4.5 CM850, 2250, 2250 EC, B4.5 RGT

Cummins ISB, QSB5.9-44. 5.9-30. B5.9. 6B

Cummins ISB, QSB6.7 CM850. 2150. 2150 SN. 2150 SQ, 2250. 2250 EC

Cummins ISC. QSC8.3 CM554, 850, 2150, 2250, C8.3

Cummins ISF2.8 CM2220 (AN. EC. IAN)

Cummins ISF3.8 CM2220 (AN. IAN)

Cummins ISL. QSL8.9, 9 CM554. 850. 2150. 2250

Cummins ISL9 CM2350 1101

Cummins ISM CM570, 570/870, 875, 876, ISMe CM570, QSM11 CM570

Cummins ISX11.9, QSX11.9 CM2250, 2250 ECF, 2350 X102

Cummins ISX12 G CM2180 EJ

Cummins ISX15, QSX15 CM570, 870, 871, 2250, 2250 SN, 2250 ECF, 23

Cummins ISZ13 CM2150

Cummins L Gas Plus

Cummins L10

Cummins L10 Gas

Cummins M11

Cummins N14 CELECT, CELECT Plus, NH, NT

Cummins QSB3.3 CM2150, 2250 EC, B3.3

Cummins QSB3.3 CM2250

Cummins OS83.9-30, B3.9. 4B3.9

Cummins QSB4.5-30, B4.5

Cummins QSD2.0, 2.8 Marine

Cummins QSK19 CM500, 850, 2150, K19

Cummins QSK19G, K19 G, G19

Cummins QSK23 CM500

Cummins QSK38 CM500, 850, 2150, K38 KTA38GC CM558

Cummins QSK45 04500

Cummins QSK45G

Cummins QSK50 CM500, 850, 2150, K50

Cummins QSK60 CM500, 850, 2150

Cummins QSK60G

Cummins QSK78 CM500

Cummins QST30 CM552, 850PG

Cummins QSV81G

Cummins QSV91G

Volvo PROSIS 2017

1:13 PM

hydralicu diagrams

,

repair manuals

,

Volvo Prosis electronic spare parts catalog

,

wiring diagrams

,

workshop manuals

Volvo PROSIS 2017

Volvo Prosis electronic spare parts catalogue, workshop manuals, repair manuals, wiring diagrams, hydralic diagrams and etc for all models Wheel Loaders,

Excavators, Articulated Haulers, Akerman Excavators, Volvo Motor Graders and etc.

PROSIS – THE FASTEST WAY TO ALL THE PARTS INFORMATION YOU NEED

Parts information on VOLVO PROSIS DVD

– Parts information is stored on DVD-ROM and can be retrieved via the user-friendly system PROSIS.

– PROSIS is an abbreviation of PROduct Support Information System.

– PROSIS contains parts catalogs for just about all of Volvo Construction Equipment’s products.

Easier to use than a Parts Catalog Volvo Prosis

– If you’re used to working with parts catalog, you’ll recognize the structure in PROSIS.

– The same graphic design makes it fast for you to learn how to use PROSIS.

– The connection between the parts list and illustration makes it easy to choose the right part.

– When a row in the parts list is marked the corresponding position number lights up in the illustration.

Simple search function Volvo Prosis

– PROSIS has a very user-friendly search function.

– Activate the desired search area; Part, Heading, Figure or Equipment, by clicking on the right section.

– After entering the search conditions, the results are displayed fast.

Volvo PROSIS 2017

| Region: | All regions | |

| Languages: | English, Spanish, German, French, Japanese | |

| OS: | WinXP , Win 7 | |

| Quantity of CD: | 9 DVD |

Sunday, November 5, 2017

Mercedes EPC EWA 09.2017

Mercedes EPC EWA 09.2017

Mercedes EPC EWA 09.2017

Mercedes EPC net represents the latest development in EPC Flexible Publishing. EPC net is available both online and offline. All the functions available in EPC Flexible Publishing have been fully integrated into EPC net. The modern user interface applying standard Windows rules serves to significantly improve user guidance and navigation. Modern user interface using standard Windows rules Users will immediately note the modern user interface and the simple navigation using standard Windows rules. You can open functions using the icons (a) or the Menu bar (b). Tooltips are provided to explain icon functions (c). Hovering the mouse pointer over an icon causes the tooltip to appear with a description of the icon's function. The combined pull-down menus (d) with input fields are available in EPC net for simple navigation within the catalogs/groups/subgroups. You can use your mouse or keyboard to operate EPC net. Most of the keyboard shortcuts used in EPC Flexible Publishing are also used in EPC net. For parts identification, EPC net requires at least a 6-digit model designation. Ideally, parts identification should be done using a vehicle identification number so that the datacard can be used in the process. The datacard must be used when looking for parts that are color-specific or where the search depends on what equipment is installed in the vehicle. Reduced number of windows Functions that were spread over several windows in EPC Flexible Publishing have been condensed onto one window in EPC net.The EPC net window is subdivided into the following sections: Mercedes EPC net Picture The picture has been supplemented with different zoom functions, and can be shown in a separate window using the icon. Mercedes EPC net Parts list All the part numbers for the entire subgroup are shown in the parts list. Footnotes and code information (passenger cars), SA/component information (commercial vehicles) and construction kit information (BUS) can be displayed via links in a separate window. Mercedes EPC net Shopping list The contents of the shopping list (e.g. quantity) can be changed directly in the individual columns.One important new feature is the "Show part context" function. When you reopen a saved shopping list you can click on the part designation in the form of a mouse-sensitive blue link to extract the part context directly from the shopping list.This saves you the trouble of reentering the vehicle data and the group/subgroup. Mercedes EPC net List overview The "List overview" can help the EPC net users with shopping list administration. Saved shopping lists and a "temporary shopping list" can be used at the same time. The icon can be used to create, show, delete, copy and print shopping lists.The active area of the EPC net window is marked with a red frame. You can change the size of the individual EPC net window areas via the respective dividing lines. Double-clicking on the dividing line between the picture and the parts list causes the picture to be arranged above the parts list.updates from DVD.English, Hungarian, Dutch, Danish, Spanish, Italian, Chinese, German, Dutch, Norwegian, Polish, Russian, Turkish, French, Czech, Swedish, Japanese

winxp , win7

5 DVD

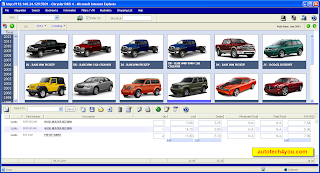

Chrysler PAIS4 07.2017

Chrysler PAIS4 07.2017

screen shoots

Chrysler International PAIS4

spare parts catalog for Chrysler, Dodge, Jeep, Plymouth, Eagle, all markets, vin decoding 1984-2017.

Chrysler International PAIS 4 Parts Information:

1985-current (all makes and models).

Accessory information.

Chrysler International PAIS 4 Languages Available:

English, French, German, Italian, Portuguese, Spanish.

Chrysler International PAIS 4 Benefits:

Fast, error-free part lookups by part name, number or code.

Part history and supersession data helps you order the most current parts and reduce your obsolete parts inventory.

Integration of parts lists with your in-house inventory system saves time and reduces errors.

Chrysler International PAIS4 Features:

VIN decoding and filtering displays vehicle-specific parts information. Monthly price book information for fewer errors (distributor pricing only). Year, model, group and figure indexes. Shortcuts save time for experienced users. Instant access to your in-house inventory system. Capacity to customize parts data by adding your own notes. Online help screens minimize new user training time. Print high-quality text and illustrations Chrysler International PAIS4 .Sunday, July 19, 2015

Caterpillar SIS 2015 Full

Caterpillar sis 01.2015

SIS is the electronic service tool that Caterpillar dealers, customers and employees rely on for their parts and service information needs. SIS provides information for all Caterpillar machines and engines from 1977. SIS is available on the Internet, DVDs and a network version based on the DVD standalone application.

SIS Web is updated continually and is the most complete and up to date version of SIS. SIS DVD and Network SIS use the same information that is located on the monthly data DVD'S. The time required to stage and ship the DVD'S to Dealer's and Customer's accounts for the delay in information that may be available from SIS DVD/Network.

SIS DVD is the standalone version of SIS and is required when the Caterpillar Inc. server for either SIS Web or the Dealer server for Network SIS is not available. Field Mechanics may be the largest group that uses SIS DVD. All three versions of SIS require an Internet Browser to display SIS information.

Caterpillar STW

The Service Technician Workbench is an integrated package of software tools, designed to assist the Caterpillar Service Technician during the machine repair process.

STW provides common installation of the following service software applications: STW Toolbar (STW Lauchpad), Service Information System (SIS), Cat Electronic Technician (Cat ET), CBT Component Based Troubleshooting (CBT), Technical Analisis I (TA1) & Technical Analisis II (TA2), and Service Report.

STW Features:

Allows user to send data from SIS, TA and Cat ET to an Electronic Service Report. All information about the repair is in one location.

Allows user to attach Cat ET Warranty Reports to the STW service report.

Allows user to attach digital photos to further document the repair.

A single source of support ? DDS Support Center

Electronic service reports are easier to archive than paper service reports.

Integration between Component Based Troubleshooting (CBT), Service Information System (SIS), Cat Electronic Technician (Cat ET), Flash File Search and Service Report.

The DBS Upload utility increases dealer efficiency by eliminating the need for the technician to re-type data into the service report, already created in DBS. This information is sent from DBS to STW to create a STW service report.

STW Lauchpad

The STW Launchpad allows to you: Conveniently launch Service Software Applications, Manage some common SIS/CBT preferences.

STW Service Report

The STW Service Report is a tool to help you collect, report, and organize your service jobs.

- Allows for complete documentation of your repair.

- Reduce duplicate typing of Service Reports

- Easy to read

- Spell check

Easy integration with Dealer Business System (both DBS and DBSi):

Download header information from DBS

Upload service information to DBS after your job is completed

Collect information from other service tools, including:

Parts lists from SIS

ECM summaries and reports from Cat ET

Inspection lists from Technical Analysis (TA)

Component Based Troubleshooting

Component Based Troubleshooting (CBT) helps the technician troubleshoot symptoms and codes for Caterpillar engines and machines. After identifying a symptom, the technician is presented with a list of components that, if not operating properly, may cause the symptom. By using the information provided for each component, the technician can identify the root cause of the symptom and fix the problem. The technician is also presented with a list of available ECMs and codes for the selected model to troubleshoot diagnostic codes. In addition, CBT gives the technician links to related information for symptoms and codes in the Service Information System (SIS).

Total:19 DVDs. (2 DVD + 17 DVD DL)

Disc #1: DVDD0001-11 PRODUCT SUPPORT INFORMATION

Disc #2: DVDD0002-11 ELECTRIC POWER GENERATION

Disc #3: DVDD0003-11 MARINE ENGINES, PETROLEUM PRODUCTS, TRUCK ENGINES

Disc #4: DVDD0004-11 INDUSTRIAL ENGINES

Disc #5: DVDD0005-11 EXCAVATORS, OEM PRODUCTS

Disc #6: DVDD0006-00 PIPELAYERS, TRACK TYPE TRACTORS

Disc #7: DVDR0007-89 INTEGRATED TOOLCARRIERS, WHEEL TYPE LOADERS, WHEEL TRACTOR SCRAPERS

Disc #8: DVDR0008-85 WHEEL TYPE LOADERS

Disc #9: DVDR0009-62 ARTICULATED DUMP TRUCKS, LOAD HAUL DUMP, MACHINE CONTROL GUIDANCE PRODUCTS, OFF HIGHWAY TRUCKS, UNDERGROUND ARTICULATED TRUCKS, ON HIGHWAY TRUCKS

Disc #10: DVDR0010-46 BACKHOE LOADERS, CHALLENGERS, COMBINES, MINI EXCAVATORS, SKID STEER LOADERS, TILLAGE, TELSCOPIC MATERIAL HANDLERS, WORK TOOLS

Disc #11: DVDR0011-33 ASPHALT PAVERS, COLD PLANERS, COMPACTORS, MOTOR GRADERS, ROAD RECLAIMERS

Disc #12: DVDR0012-25 EXCAVATORS

Disc #13: DVDR0013-25 TRACK TYPE TRACTORS

Disc #14: DVDR0014-11 EXCAVATORS, OEM PRODUCTS

Disc #15: DVDR0015-02 EXCAVATORS

SIS Web is updated continually and is the most complete and up to date version of SIS. SIS DVD and Network SIS use the same information that is located on the monthly data DVD'S. The time required to stage and ship the DVD'S to Dealer's and Customer's accounts for the delay in information that may be available from SIS DVD/Network.

SIS DVD is the standalone version of SIS and is required when the Caterpillar Inc. server for either SIS Web or the Dealer server for Network SIS is not available. Field Mechanics may be the largest group that uses SIS DVD. All three versions of SIS require an Internet Browser to display SIS information.

Caterpillar STW

The Service Technician Workbench is an integrated package of software tools, designed to assist the Caterpillar Service Technician during the machine repair process.

STW provides common installation of the following service software applications: STW Toolbar (STW Lauchpad), Service Information System (SIS), Cat Electronic Technician (Cat ET), CBT Component Based Troubleshooting (CBT), Technical Analisis I (TA1) & Technical Analisis II (TA2), and Service Report.

STW Features:

Allows user to send data from SIS, TA and Cat ET to an Electronic Service Report. All information about the repair is in one location.

Allows user to attach Cat ET Warranty Reports to the STW service report.

Allows user to attach digital photos to further document the repair.

A single source of support ? DDS Support Center

Electronic service reports are easier to archive than paper service reports.

Integration between Component Based Troubleshooting (CBT), Service Information System (SIS), Cat Electronic Technician (Cat ET), Flash File Search and Service Report.

The DBS Upload utility increases dealer efficiency by eliminating the need for the technician to re-type data into the service report, already created in DBS. This information is sent from DBS to STW to create a STW service report.

STW Lauchpad

The STW Launchpad allows to you: Conveniently launch Service Software Applications, Manage some common SIS/CBT preferences.

STW Service Report

The STW Service Report is a tool to help you collect, report, and organize your service jobs.

- Allows for complete documentation of your repair.

- Reduce duplicate typing of Service Reports

- Easy to read

- Spell check

Easy integration with Dealer Business System (both DBS and DBSi):

Download header information from DBS

Upload service information to DBS after your job is completed

Collect information from other service tools, including:

Parts lists from SIS

ECM summaries and reports from Cat ET

Inspection lists from Technical Analysis (TA)

Component Based Troubleshooting

Component Based Troubleshooting (CBT) helps the technician troubleshoot symptoms and codes for Caterpillar engines and machines. After identifying a symptom, the technician is presented with a list of components that, if not operating properly, may cause the symptom. By using the information provided for each component, the technician can identify the root cause of the symptom and fix the problem. The technician is also presented with a list of available ECMs and codes for the selected model to troubleshoot diagnostic codes. In addition, CBT gives the technician links to related information for symptoms and codes in the Service Information System (SIS).

Total:19 DVDs. (2 DVD + 17 DVD DL)

Disc #1: DVDD0001-11 PRODUCT SUPPORT INFORMATION

Disc #2: DVDD0002-11 ELECTRIC POWER GENERATION

Disc #3: DVDD0003-11 MARINE ENGINES, PETROLEUM PRODUCTS, TRUCK ENGINES

Disc #4: DVDD0004-11 INDUSTRIAL ENGINES

Disc #5: DVDD0005-11 EXCAVATORS, OEM PRODUCTS

Disc #6: DVDD0006-00 PIPELAYERS, TRACK TYPE TRACTORS

Disc #7: DVDR0007-89 INTEGRATED TOOLCARRIERS, WHEEL TYPE LOADERS, WHEEL TRACTOR SCRAPERS

Disc #8: DVDR0008-85 WHEEL TYPE LOADERS

Disc #9: DVDR0009-62 ARTICULATED DUMP TRUCKS, LOAD HAUL DUMP, MACHINE CONTROL GUIDANCE PRODUCTS, OFF HIGHWAY TRUCKS, UNDERGROUND ARTICULATED TRUCKS, ON HIGHWAY TRUCKS

Disc #10: DVDR0010-46 BACKHOE LOADERS, CHALLENGERS, COMBINES, MINI EXCAVATORS, SKID STEER LOADERS, TILLAGE, TELSCOPIC MATERIAL HANDLERS, WORK TOOLS

Disc #11: DVDR0011-33 ASPHALT PAVERS, COLD PLANERS, COMPACTORS, MOTOR GRADERS, ROAD RECLAIMERS

Disc #12: DVDR0012-25 EXCAVATORS

Disc #13: DVDR0013-25 TRACK TYPE TRACTORS

Disc #14: DVDR0014-11 EXCAVATORS, OEM PRODUCTS

Disc #15: DVDR0015-02 EXCAVATORS

.png)